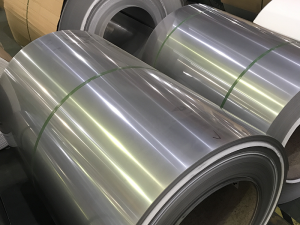

410S Stainless Steel Coil

Katrangan

Spesifikasi:

1. Standar: ASTM A240, JIS G4304, EN10088

2. Kelas: 200seri&300seri&400seri

3. Kekandelan: 0.03mm - 6.0mm

4. Jembar: 8mm-600mm

5. Length: minangka request pelanggan

6. Lumahing: 2D, 2B, BA, Mirror rampung, N04, Garis Rambut, Matt finish, 6K, 8K

7. Teknologi: kadhemen digambar / kadhemen mbalek / panas mbalek

Bahan:

| Jinis | sasmita | sasmita | Komponen kimia % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Liyane | |||

| Austenitik | 201 | SUS201 | ≤0,15 | 16.00-18.00 | 3.50-5.50 | 5.50–7.50 | ≤0,060 | ≤0,030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0,15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0,060 | ≤0,030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0,15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0,07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0,030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0,030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0,030 | ≤0,020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0,035 | ≤0,020 | 3.0-5.0 | ≤0,80 | 0.5 | 0.24-0.32 | ||

| ferit | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0,040 | ≤0,020 | - | ≤1.00 | - | ≤0,030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0,040 | ≤0,030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0,025 | 17.50-19.50 | 1 | ≤1.00 | ≤0,040 | ≤0,030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensit | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0,080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0,07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | ≤0,50 | - | Al 0,75-1,50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0,040 | ≤0,030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0,75-1,50 | |

Informasi dhasar

410s Stainless Steel Coil, kanthi resistensi karat lan kemampuan mesin sing apik, yaiku baja tujuan umum lan baja alat pemotong.410S punika jenis baja kang bisa nambah resistance karat lan formability saka 410 steel.410S punika baja kekuatan dhuwur kang luwih bisa nambah resistance karat saka 410 baja.Iki digunakake kanggo agul-agul turbin lan bagean suhu dhuwur.

• Spesifikasi: AISI 410s, ASTM 410s

• Rampung: lumahing Ba, lumahing 2b, No.1 (kulit putih), lumahing 2D, No.4 (frosted), HL (gambar kabel), lumahing 8K duwe kualitas lumahing banget

•Toleransi pabrik ing kekandelan & flatness ditrapake. Telpon JM Steel yen sampeyan butuh ukuran tartamtu utawa arah gandum.

410S teknologi mesin karakteristik

1D -- Lumahing nduweni wangun granular sing ora terus-terusan, uga dikenal minangka permukaan kabut.

Teknologi pangolahan: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2D - Werna putih rada perak.

Teknologi pangolahan: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2B -- Putih salaka kanthi gloss lan flatness luwih apik tinimbang lumahing 2D.

teknologi Processing: rolling panas + annealing dijupuk peening pickling + rolling kadhemen + annealing pickling + quenching lan tempering rolling.

Ba - Kilap permukaan sing apik banget, reflektivitas dhuwur, kaya permukaan pangilon.

teknologi Processing: rolling panas + annealing dijupuk peening pickling + rolling kadhemen + annealing pickling + polishing lumahing + quenching lan tempering rolling.

No.3 -- Kinclong apik, lumahing gandum kasar.

Teknologi Processing: polishing lan tempering rolling kanggo 2D utawa 2B karo 100 ~ 120 bahan abrasive (JIS R6002).

No.4 -- Kinclong apik, garis-garis alus ing permukaan.

Proses pangolahan: polishing lan tempering rolling kanggo 2D utawa 2B karo 150 ~ 180 bahan abrasive (JIS R6002).

HL -- abu-abu salaka kanthi garis rambut.

Teknologi pangolahan: Produk 2D utawa produk 2B kanthi granularitas bahan abrasif sing cocog kanggo polishing lumahing minangka gandum abrasif sing terus-terusan.

MIRRO -- Specular.

Teknologi pangolahan: produk 2D utawa produk 2B kanthi granularitas sing cocog saka grinding lan polishing materi kanggo efek pangilon.