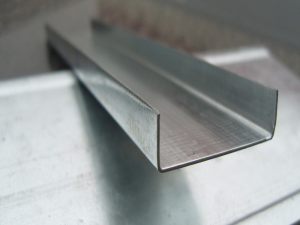

Strip Baja Tahan Karat

Informasi dhasar

✔ Strip baja tahan karat 304 duwe macem-macem panggunaan.Apa ing omah utawa ing pawon, utawa sampeyan minangka penggemar DIY, sampeyan bisa nyiyapake sawetara amarga sampeyan bakal nggunakake.

✔ Strip baja tahan karat 304 digawe saka baja tahan karat 304 premium sing nduweni kinerja tahan karat & karat lan populer banget sajrone urip saben dina.

✔ Shims eetal baja tahan karat nduweni elastisitas sing dhuwur, ketangguhan sing apik, sampeyan bisa kanthi gampang mlengkung lan jalur baja tahan karat bisa dipotong, dibor, disolder, utawa dibentuk ing macem-macem bagean.

✔ Sampeyan bakal entuk 10 lembar baja lembaran baja tahan karat sing dawane 12 inci, ambane 1 inci, kandel 0,024 inci, kanthi tutup peel PVC protèktif sing njamin siji sisih bakal rampung cermin.

✔ Simpenan shim baja tahan karat digunakake ing DIY, mesin presisi, manufaktur cetakan, manufaktur hardware, lan pengisi celah pawon lan lsp.

KEUNTUNGAN STAINLESS STEEL

Baja tahan karat minangka produk teknik sing populer, lan panggunaan materi iki ing teknik umume.Kanthi ketahanan korosi sing apik lan kemampuan mesin sing unggul, strip baja tahan karat bisa digunakake ing industri.Aplikasi umum kalebu sektor pasar kayata otomotif, HVAC (pemanasan, ventilasi, AC), kimia, pangolahan panganan, pendinginan lan konstruksi.

GUNA beda

Saben kelas nawakake karakteristik kinerja sing beda.Conto kalebu 301 strip stainless, kang kelas austenitic digunakake ing mbentuk spring tanpa perlu kanggo perawatan panas luwih.304 stainless non-Magnetik ing negara anil lan digunakake ing stampings lan digambar bagean.

Fitur

Strip baja tahan karat 304 duwe macem-macem panggunaan.Apa ing omah utawa ing pawon, utawa sampeyan minangka penggemar DIY, sampeyan bisa nyiyapake sawetara amarga sampeyan bakal nggunakake.

Strip baja tahan karat 304 digawe saka baja tahan karat 304 premium sing nduweni kinerja tahan karat & karat lan populer banget sajrone urip saben dina.

Shims eetal stainless steel duwe elastisitas dhuwur, kateguhan sing apik, sampeyan bisa kanthi gampang mbengkongake lan jalur baja tahan karat bisa dipotong, dilatih, disolder, utawa dibentuk ing macem-macem bagean.

Simpenan shim stainless steel digunakake ing DIY, mesin presisi, manufaktur cetakan, manufaktur hardware, lan pengisi celah pawon lan ect.

Sampeyan bakal entuk 10 lembar baja lembaran baja tahan karat sing dawane 12 inci, ambane 1 inci, kandel 0,024 inci, kanthi tutup pelindung PVC protèktif sing njamin siji sisih bakal rampung cermin.

Katrangan

| Jinis | sasmita | sasmita | Komponen kimia % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Liyane | |||

| Austenitik | 201 | SUS201 | ≤0,15 | 16.00-18.00 | 3.50-5.50 | 5.50–7.50 | ≤0,060 | ≤0,030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0,15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0,060 | ≤0,030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.431 | ≤0,15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0,07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0,030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0,030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.455 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| xm-19 | Nitronik50 | ≤0.06 | 20.50-23.50 | 11.50-13.50 | 4.0-6.0 | ≤0,045 | ≤0,030 | 1.50-3.00 | ≤1.00 | - | 0.2-0.4 | Nb: 0.10-0.30 V: 0.10-0.30 | |

| 904L | N08904 | ≤0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0,045 | ≤0,035 | ≤1.00 | 0.1 | Cu: 1.0-2.0 | |||

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0,030 | ≤0,020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0,035 | ≤0,020 | 3.0-5.0 | ≤0,80 | 0.5 | 0.24-0.32 | ||

| * | S32760 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.00 | ≤0,030 | ≤0,010 | 3.0-4.0 | ≤1.00 | 0.5-1.00 | 0.2-0.3 | ||

| 2304 | S32304 | ≤0.03 | 21.5-24.5 | 3.0-5.5 | ≤2,50 | ≤0,040 | ≤0,030 | 0.05-0.6 | ≤1.00 | 0.05-0.6 | 0.05-0.2 | ||

| 329 | 1.446 | ≤0.08 | 23.00-28.00 | 2.00-5.00 | ≤1.00 | ≤0,040 | ≤0,030 | 1.00-2.00 | ≤0,75 | - | - | ||

| ferit | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0,040 | ≤0,020 | - | ≤1.00 | - | ≤0,030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0,040 | ≤0,030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0,025 | 17.50-19.50 | 1 | ≤1.00 | ≤0,040 | ≤0,030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| 446 | S44600 | ≤0.20 | 23.00-27.00 | 0.75 | ≤1.5 | ≤0,040 | ≤0,030 | 1.50-2.50 | ≤1.00 | - | ≤0.25 | - | |

| Martensit | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0,080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 416 | Y1Cr13 | ≤0,15 | 12.00-14.00 | 3) | ≤1.25 | ≤0,060 | ≥0.15 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 431 | 1Cr17Ni2 | ≤0.20 | 15.00-17.00 | 1.50-2.50 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤0,80 | - | - | - | |

| 440C | 11Kr17 | 0.95-1.20 | 16.00-18.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | 0.75 | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0,07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | ≤0,50 | - | Al 0,75-1,50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0,040 | ≤0,030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0,75-1,50 | |

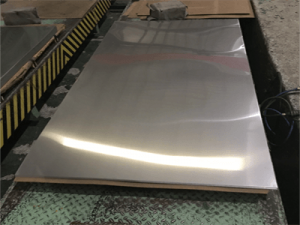

Stainless Steel Lembar Plate Grade Baogu Supply

| Rampung lumahing | Karakteristik lan aplikasi |

| 2B | Padhang lumahing lan flatness saka ora 2B luwih apik tinimbang no2D.banjur liwat perawatan lumahing khusus kanggo nambah sifat mekanik sawijining, No2B meh bisa gawe marem nggunakake lengkap. |

| No.1 | Dipoles karo sabuk abrasive saka grit # 100- # 200, duwe padhang luwih apik karo stria coarse pedhot, digunakake minangka ornamen njero lan njaba kanggo bangunan, Perkakas listrik lan utensils pawon etc. |

| No.4 | Dipoles karo sabuk abrasive saka grit # 150- # 180, duwe padhang luwih apik karo stria coarse pedhot, nanging luwih tipis tinimbang No3, digunakake minangka bathtub bangunan njero lan njaba ornamen electrical Perkakas utensils pawon lan peralatan Processing pangan etc. |

| HL | Dipoles karo sabuk abrasive saka grit # 150- # 320 ing NO.4 Rampung lan wis garis-garis terus, utamané digunakake minangka ornamen bangunan elevator, lawang bangunan, frontal plate etc. |

| BA | Cold mbalek, padhang annealed lan kulit-liwati, produk duwe padhang banget lan reflexivity apik kaya pangilon, apparatus pawon, ornamen etc. |

| 8K | Produk kasebut duwe padhang banget lan luwih seneng reflekstivitas dadi pangilon. |